High Phosphorus Electroless Nickel Plating

Micro Plating offers RoHS and REACH compliant High Phosphorus Electroless Nickel Plating conforming to AMS 2404 Spec, AMS 2454 Spec, AMS-C-26074 Spec, ASTM B733 Spec, Mil-C-26074, MILDTL-32119 Spec, and more.

Learn about the Benefits of High Phosphorus Electroless Nickel Plating, including its hardness, deposit uniformity, and corrosion resistance.

HARDNESS

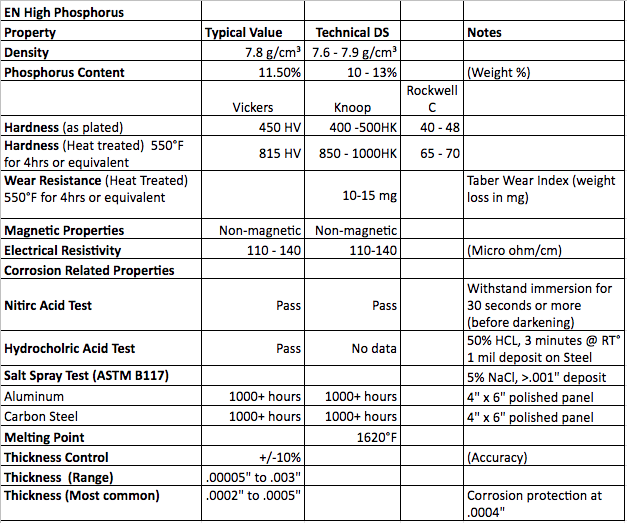

High Phosphorus Electroless Nickel plating provides substantial hardness, making it ideal for military applications and high-impact environments including molds repairs. This plating solution is made of an alloy including 10-12% Phosphorus and provides approximate 48-52 Rc of hardness as-plated. For jobs demanding greater wear resistance, heat treating our High Phosphorus Nickel Plating can increase its hardness to 68-70 Rc. Thanks to its hardness and lack of porosity at thicknesses above .0004”, this plating solution is ideal for substrates intended for demanding work and use in high impact environments.

UNIFORMITY

Traditional electroplating problems including uneven thickness, lack of plating in recesses and corners, and edge build up can be avoided with High Phosphorus Electroless Nickel Plating. The chemical depositing method of our High Phosphorus Nickel guarantees 100% coverage. This uniform depositing removes the need for post-plating polishing and machining that some plating methods require to ensure a consistent finish. The uniformity of Micro Plating’s High Phosphorus Nickel Plating in PA combined with our ability to control the deposit’s thickness makes it an ideal solution for threaded substrates and objects with complex geometries.

CORROSION RESISTANCE

When substrates call for military or aerospace grade corrosion resistance, High Phosphorus Electroless Nickel Plating may be the ideal solution. Our coatings meet or exceed Mil-C-26074 Spec, MILDTL-32119 Spec, AMS 2404 Spec, AMS 2454 Spec, and more. We have the in-house laboratory and advanced testing equipment needed to ensure our alloys meet the desired specifications for every application. The uniform application and high level of phosphorus in this plating provides maximum corrosion protection for substrates it is applied to. Given its durable nature, our High Phosphorus Electroless Nickel plating can allow customers to substitute less stainless steels and other hard to machine alloys for less costly substrates. Based on ASTM B117 salt spray tests, our plating outperforms electroless nickel plating solutions with 9% or less phosphorus by greater than 4 to 1.

High Phosphorus Electroless Nickel Plating

Benefits & Features

- Superior corrosion protection with 10-12% phosphorus

- Low to zero porosity depending on thickness of buildup

- High Phosphorus Electroless Nickel is a Non-magnetic coating

- Less prone to staining

- Uniform, Pit-free electroless nickel deposits

- Compressive stress tested

- Hardness of heat treated electroless nickel is comparable to hard chrome

- Deposits uniformly regardless of part geometry

- Semi-bright appearance is like stainless steel.

CONTACT US

Footer form

We will get back to you as soon as possible.

Please try again later.

Location

8110 Hawthorne Dr.Erie, Pa 16509

Contact Us

Micro Plating Inc. | All Rights Reserved |

Created by Olive + Ash.

Managed by Olive Street Design.