MicroLube: A Proprietary Electroless Nickel Composite Plating Solution with PTFE particles for high Friction Applications

MicroLube is a unique REACH and RoHS compliant plating solution that offers high lubricity

and reliable corrosion resistance to diverse types of base metals

ABOUT

MICROLUBE

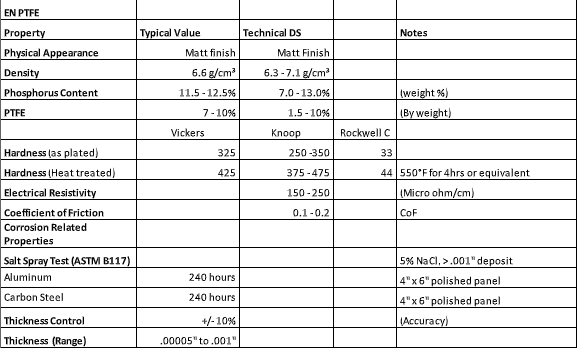

At Micro Plating, Inc, our team is focused on providing plating solutions that solve challenges faced in high friction and wear applications. In addition to popular solutions including high-phosphorus electroless nickel and mid-phosphorus electroless nickel, we have developed proprietary plating solutions to solve unique plating challenges. One example is our MicroLube electroless nickel composite plating process, which includes PTFE. PFTE is a compound that is hydrophobic, friction resistant, able to handle high temperatures, non-wetting, and high density. Our process of depositing our proprietary MicroLube plating, we have developed a means of ensuring that PTFE is evenly distributed throughout the deposit to ensure optimum performance. In addition to this uniform application and 100% coverage, MicroLube will result in no edge build-up, even when applied to substrates with complex shapes. We can apply this proprietary coating with a thickness range of .00005” to .001”, though thickness commonly ranges between .002” - .003”. With these beneficial characteristics, MicroLube makes for an ideal coating solution in a diverse range of applications.

FRICTION / LUBRICITY

When a substrate will face sliding wear or be involved in well distributed mild weight loads and needs a coating with a low frictional value, MicroLube makes for an excellent choice. MicroLube is particularly useful for non-lubricated wear applications and can be used to extend part life by reducing the impact of friction. One situation where MicroLube has proven beneficial is as a plastic molding release coating thanks to its uniform application, its ability to handle friction and its anti-stick properties. If you have a coating job that requires high friction resistance and uniform application, we recommend contacting us to learn more about how MicroLube can serve your anti-corrosion coating needs.

CORROSION RESISTANCE

Often, a metal substrate can be ideal for an application due to its weight, malleability, or other qualities, but lacks the natural corrosion resistance its application demands. This is where a corrosion resistant coating like MicroLube comes in. This coating provides 96 to 240 hours of salt spray resistance meeting the ASTM B-117 specification at 0.5mm to 1.0mm, and can protect against acids, solvents, and oils. In addition to the hydrophobic and friction resistant qualities of MicroLube, its inclusion of high phosphorus content provides for enhanced corrosion resistance. When needed, we can provide a double layer of corrosion protection to a substrate by first depositing our standard High Phosphorus Electroless Nickel coating followed by a deposit layer of MicroLube proprietary electroless nickel composite coating. This duplex coating solution is intended to provide an extra layer of protection from corrosion, sticking, wear, and galling for high impact applications. Whether applied on top of our High Phosphorus Electroless Nickel coating or as a single deposit, our MicroLube coating can be heat treated to further increase its inherent corrosion resistance.

MICROLUBE COATING FEATURES

- RoHS and REACH compliant coating Proprietary to Micro Plating Inc.

- Hydrophobic nature provides dry lubrication, reducing sticking and galling.

- Excellent for low load and high friction applications.

- Provides excellent mold release, eliminating spray releases.

- Coating is hydrophobic which helps resist corrosion.

- Heat treatment can improve MicroLube’s inherent hardness.

- Hydrophobic PTFE content can be adjusted depending on application.

- MicroLube is deposited evenly, even on substrates with complex shapes.

- No expensive anodes, jigs or fixtures required for application.

- MicroLube can be stripped from steel and aluminum without damage.

- Provides low coefficient of friction for environments including mold releases.

CONTACT US

Footer form

We will get back to you as soon as possible.

Please try again later.

Location

8110 Hawthorne Dr.Erie, Pa 16509

Contact Us

Micro Plating Inc. | All Rights Reserved |

Created by Olive + Ash.

Managed by Olive Street Design.