Electroless Nickel High Phosphorus Plating Benefits

Electroless Nickel High Phosphorus Plating Benefits

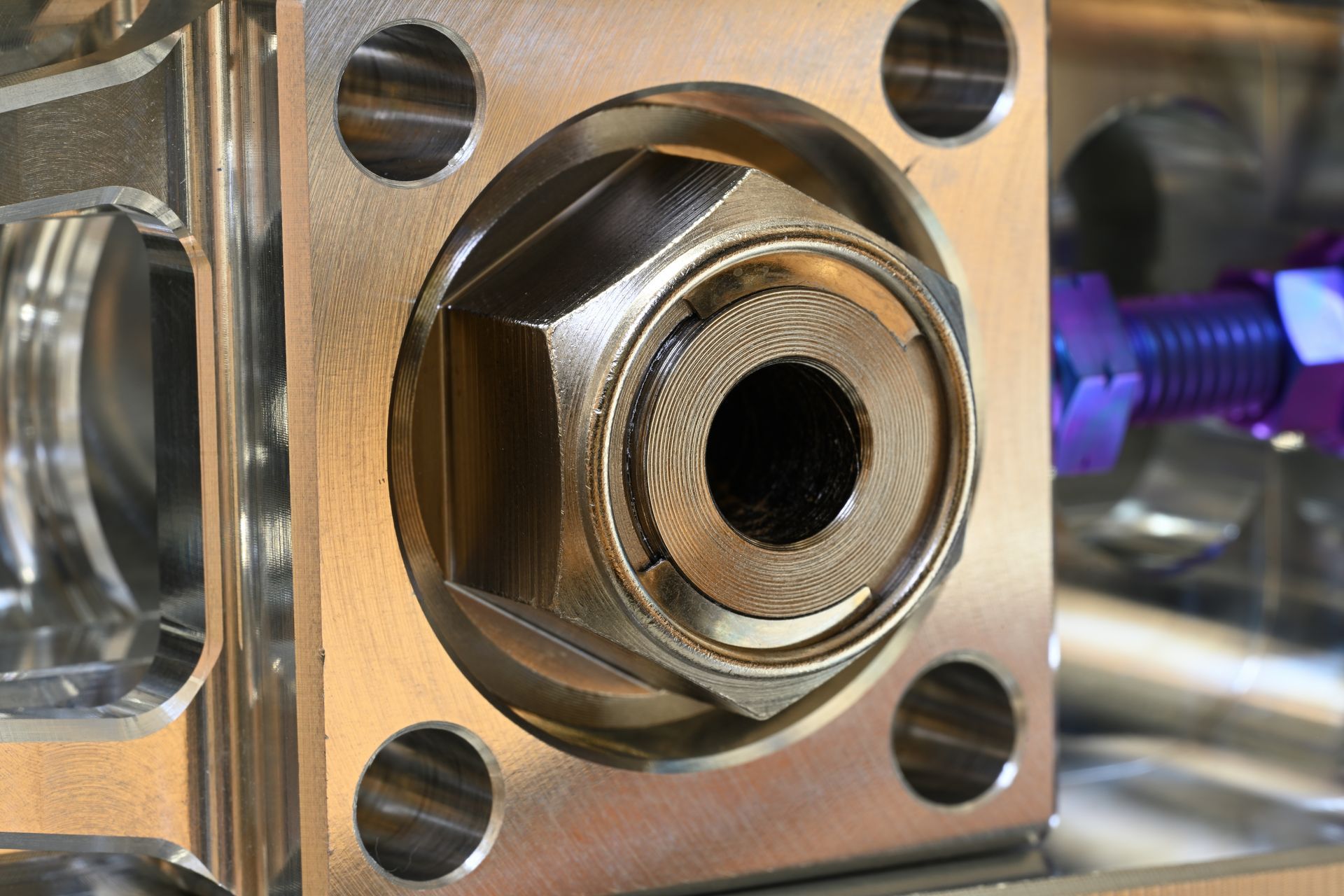

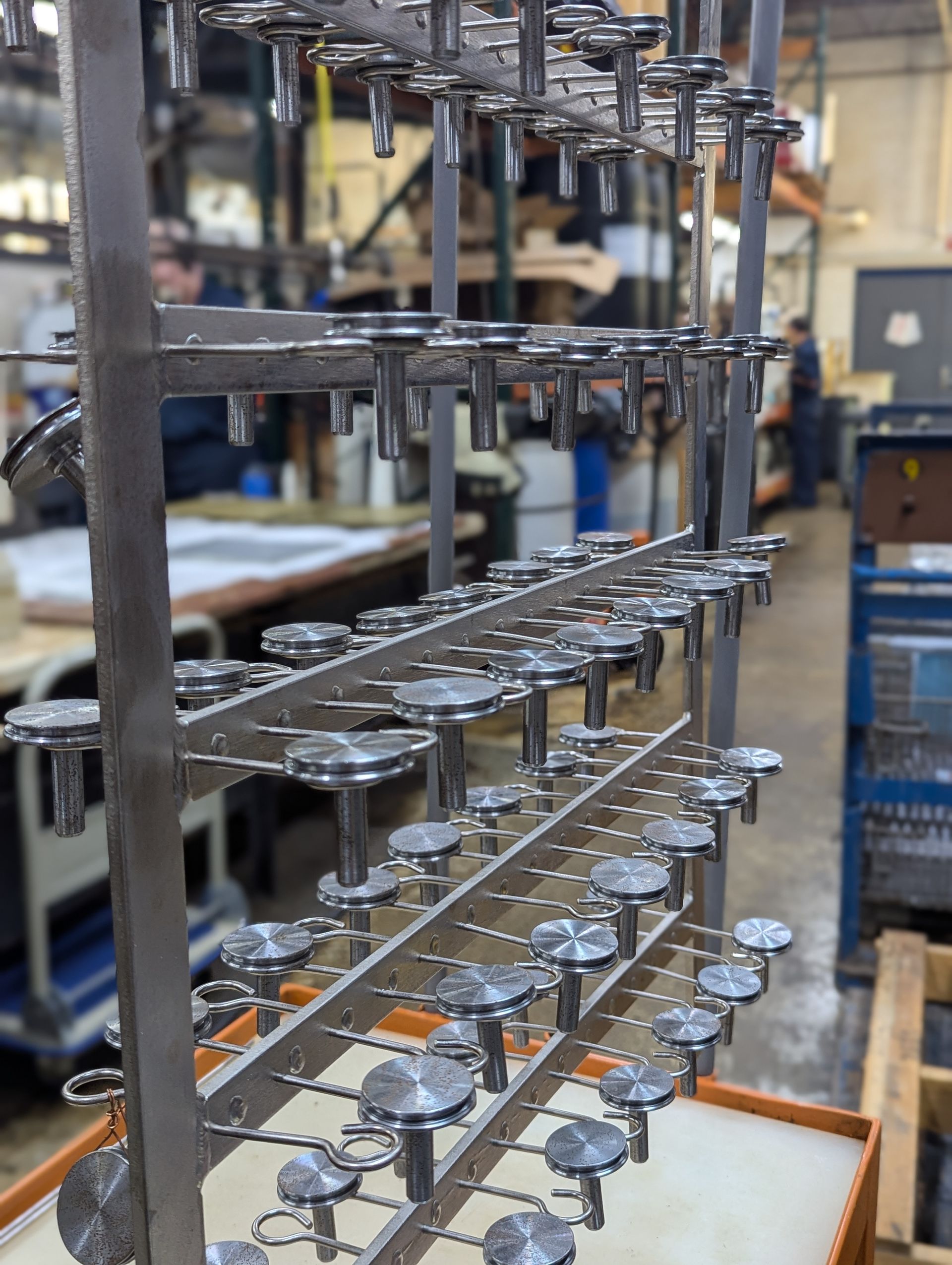

Electroless nickel with high phosphorus is the coating to choose for parts exposed to corrosive environments and rough impacts. On this page you can learn some of the key Electroless Nickel High Phosphorus Plating Benefits that have helped make this non-magnetic coating so popular.

Below, you will also be able to develop an understanding of what exactly constitutes a high phosphorus nickel alloy as well as some of the benefits of this plating solution that go beyond its functional qualities. If you have a part or product that would benefit from an electroless plating solution with extraordinary hardness as plated, substantial corrosion resistance, and an attractive appearance, contact Micro Plating for a quote.

Request High Phosphorus Nickel Plating

What Percentage of Phosphorus in Nickel Counts as High Phosphorus

With a general term like ‘high phosphorus’, you may wonder what percentage of phosphorus is involved in this electroless nickel plating solution. At Micro Plating we consider a nickel alloy including 10-12% phosphorus to constitute a high phosphorus alloy. For comparison, a medium phosphorus solution from Micro Plating will include 6-9% phosphorus depending on the given application. With this definition now complete we will move on to discuss some of the benefits of Electroless Nickel High Phosphorus Plating.

Corrosion Resistance is Extraordinary with a High Phosphorus Nickel Alloy

We referred above to our high phosphorus nickel alloys as being extraordinary in their corrosion resistance. We now want to quantify this for your benefit. In comparison to even our durable medium phosphorus alloys, our high phosphorus solutions exceed their corrosion resistance by a ratio of 4:1. This outperformance is based on the results of ASTM B117 salt spray testing.

This is one of the primary Electroless Nickel High Phosphorus Plating Benefits that has made this alloy popular in Mil-Spec and Aerospace work. Examples of specs we commonly adhere to when performing high phosphorus electroless plating work include MILDTL-32119, Mil-C-26074, AMS specification 2404, and more.

Electroless Plating with Flexible Hardness Using a High Phosphorus Nickel Solution

Above, we mentioned the range of phosphorus used in our high phosphorus nickel alloys. The reason for this range is related in part to the hardness the object to be plated requires. This alloy will provide your substrates with a coating that has a hardness rating of 48-52 Rc. In nearly any environment, this will provide your parts with more than enough protection from impact and weight in any machining process it is involved in. However, if you have a rare scenario where greater hardness would be beneficial, we can heat treat the electroless plated part for to raise its hardness. When heat treated high phosphorus electroless nickel plating will possess hardness of 68-70 Rc, which is comparable to hard chrome.

Aesthetic Benefits of High Phosphorus and Nickel Alloy Plating

Up to this point focused so far on the functional aspects of high phosphorus electroless nickel plating, there is more to this solution than corrosion resistance and hardness. Another of the Electroless Nickel High Phosphorus Plating Benefits is our ability to apply this plating uniformly. Additionally, this high phosphorus nickel alloy is less prone to staining than alloys with less phosphorus in their makeup.

Choose Micro Plating as Your RoHS Compliant Electroless Plating Company

Have you found the above information helpful in expanding your understanding the benefits of High Phosphorus electroless nickel plating? If so, we recommend contacting us to quote your next plating job. Our team possesses an average of 25 years of coating experience and loves taking on new customers while always ensuring that our long-term contracts are honored. We provide RoHS and REACH compliant electroless nickel plating services and specialize in alloying high phosphorus coatings. If you want to benefit from our expertise and quality assurance, contact Micro Plating for a quote today.

Request High Phosphorus Plating

CONTACT US

Footer form

We will get back to you as soon as possible.

Please try again later.

Location

8110 Hawthorne Dr.Erie, Pa 16509

Contact Us

Micro Plating Inc. | All Rights Reserved |

Created by Olive + Ash.

Managed by Olive Street Design.