The Benefits of Plating Services for Molds & Tooling

The Benefits of Plating Services for Molds & Tooling

Electroless nickel plating offers reliable protection for molds and tooling applications, especially when industries use them in environments that require lubricity and corrosion resistance. Micro Plating takes a customer-centric approach to our plating services considering your unique needs and customizing our services to meet them best. With an experienced team and Enterprise resource planning software, we can offer plating expertise and committed service.

The benefits of plating services are numerous, especially for molds and tooling. Not only does it offer advantages like resistance to corrosion, increased durability, and improved hardness, but Micro Plating’s Quality Program additionally ensures that you meet all the requirements of

ASTM, AMS, and Mil-Specs. Take a closer look at the wide range of benefits that plating services from Micro Plating can present to your business.

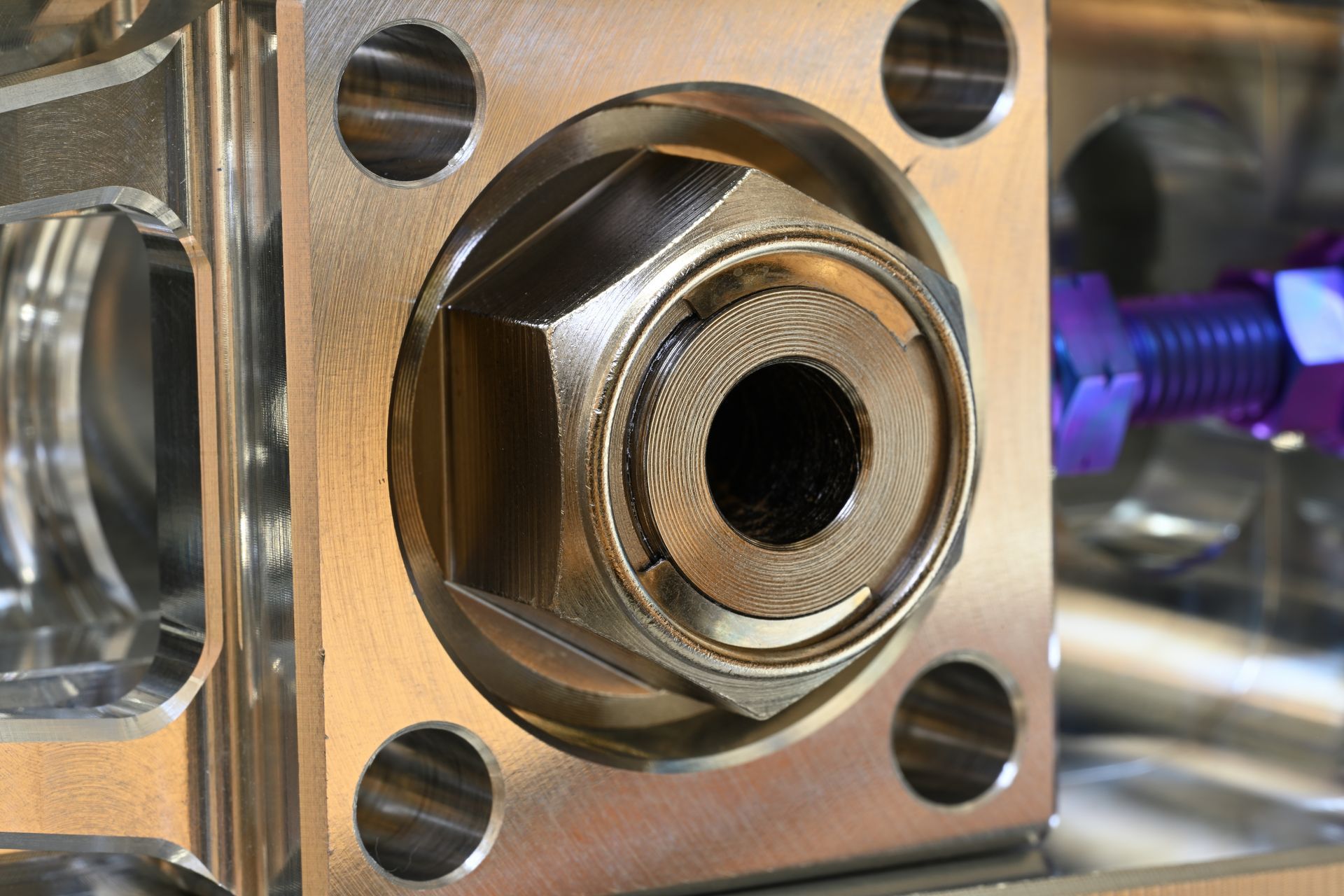

Uniform Coating on Precision Components

Molds for the automotive and aerospace industries among others often require precise specifications to make unique parts. Any kind of plating will need to offer reliable durability without compromising the precision of the mold itself. Electroless nickel plating allows for uniform coating while still maintaining the precision necessary for complex parts that have features like grooves, ridges, or recesses.

Improved Corrosion Resistance

Electroless nickel plating from Micro Plating uses phosphorus in its composition specifically to increase corrosion protection. Since the amount of corrosion protection your business may need can vary, we offer custom solutions. Our high phosphorus electroless nickel plating solution contains 10-12% phosphorus while a medium phosphorus alloy has 6-9% phosphorus. High phosphorus plating has a corrosion resistance ratio of 4:1, which makes it especially useful for applications in which molds will be exposed to corrosive environments regularly.

Optimized Durability and Lubricity

With electroless nickel plating, molds and tooling are less likely to break under stress or suffer cracks from use or pressure. Additionally, plating prevents excessive friction on tooling surfaces when used against other materials, which reduces the rate of corrosion for a long-lasting solution. Surfaces created after plating are much harder than before and are adept at resisting abrasive and water surfaces, which is a necessity for durable products. We can offer high phosphorus electroless nickel plating with a hardness of 68-70 Rc, which is similar to hard chrome.

High Temperature Range

The amount of phosphorus used in electroless nickel plated molds and tooling can affect how well it can withstand high temperatures. If you need protection for tooling that is exposed to high temperatures, our plating services can offer high phosphorus electroless nickel to help molds and tooling withstand increased temperatures without compromising dimensions and durability.

Thickness Ranges

Electroless nickel plating can be applied to molds and tooling in a range of thicknesses depending on what kind of applications are going to be utilized for the mold. At Micro Plating, we offer plating thicknesses as low as 0.0001 inches and as high as 0.0035 inches. This flexibility allows for a variety of available solutions that can be customized to your unique needs.

Aesthetic Benefits

In addition to utility, electroless nickel plating offers aesthetic benefits to molds and tooling. The uniformity is helpful for maintaining strict specifications within molds, but it also prevents staining. In fact, high phosphorus plating is more adept at preventing staining than plating without as much phosphorus in its composition.

Micro Plating Benefits

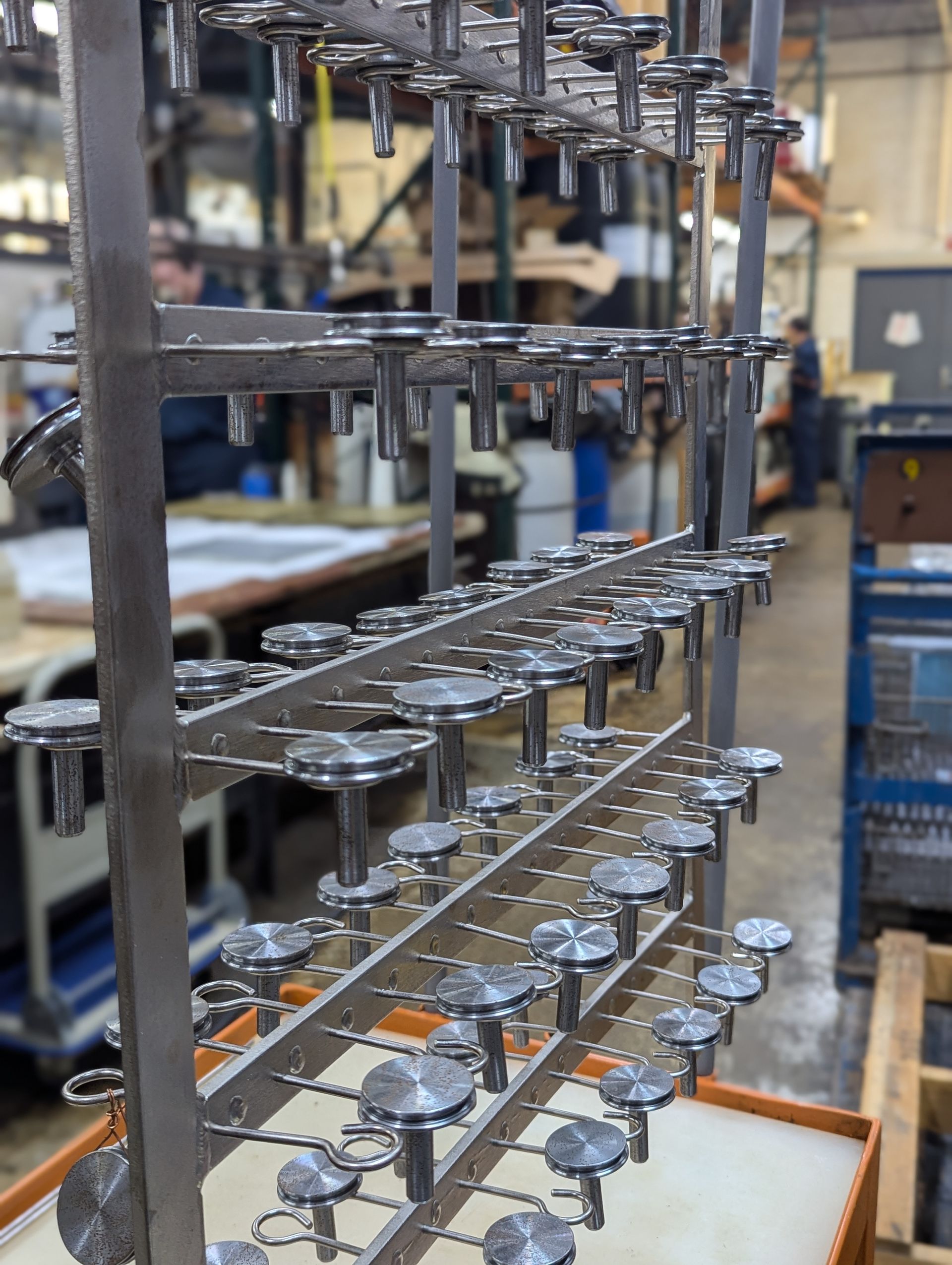

Working with us allows you to enjoy a range of additional benefits for all your molds and tooling plating needs. Our experienced team not only offers quality assurance with our testing process, but we maintain short lead times that get solutions to you quickly. We even credit samples and prototype plating to your first order. Our state-of-the-art equipment can work with a wide range of parts from just a few ounces all the way up to 250 pounds while maintaining compliance with RoHS standards.

Some of our value added services include the following:

- Heat treatment

- Packaging

- Glass bead blasting pre-treatment

Request a Quote for Plating Services for Molds and Tooling

At Micro Plating, our team guarantees quality plating services for molds and tooling by navigating a quality assurance process that maintains strict specifications and RoHS and REACH compliance. Our in-house laboratory uses X-ray fluorescence to ensure quality all leading up to a rigorous final inspection before the job is considered complete. Request a quote for your molds and tooling plating project by calling us at 814-866-0073 or by completing our online contact form.