RoHS Compliant Medium Phosphorus Electroless Nickel Plating

RoHS Compliant Medium Phosphorus Electroless Nickel Plating

RoHS Compliant Medium Phosphorus Electroless Nickel Plating

Manufacturers of parts used in electrical products need to be aware of how materials used to make those parts can run afoul of RoHS regulations. RoHS laws make it especially important to choose a competent plating company that understands what metals these laws prohibit. Micro Plating has years of experience providing RoHS compliant medium phosphorus electroless nickel plating solutions for molding equipment, making us well-suited to handling your coating needs.

Our Medium Phosphorus Platings are Safe in Electronics Devices

The RoHS regulation began being implemented 20 years ago in the European Union. Since then, other regions of the world and various US States have begun implementing their own versions that were influenced by the original EU rules.

The idea behind RoHS was to help keep consumers safe amidst the growth in electronics production. With so many new electronics entering the market and their production taking place globally, the EU believed it was important to set standards that would ban certain harmful metals from electronics designed for consumer uses. While this regulation adds another hurdle to electronics manufacturers and those who make electronics components, the good news is that in Micro Plating, you have a company that can protect the molding equipment used to make these parts while staying within the RoHS regulatory framework.

Our Medium Phosphorus Platings are Compliant with US and International RoHS Regulations

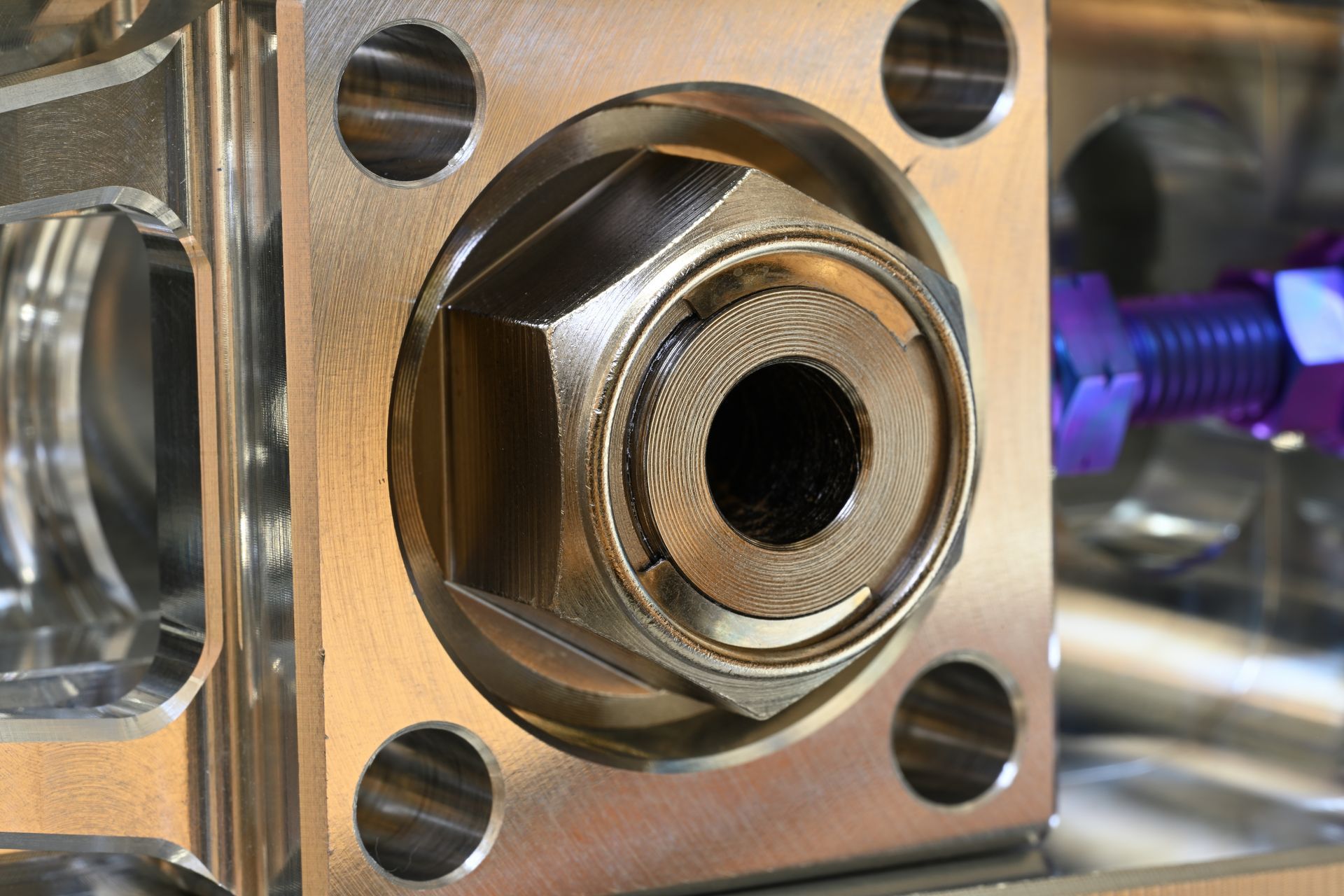

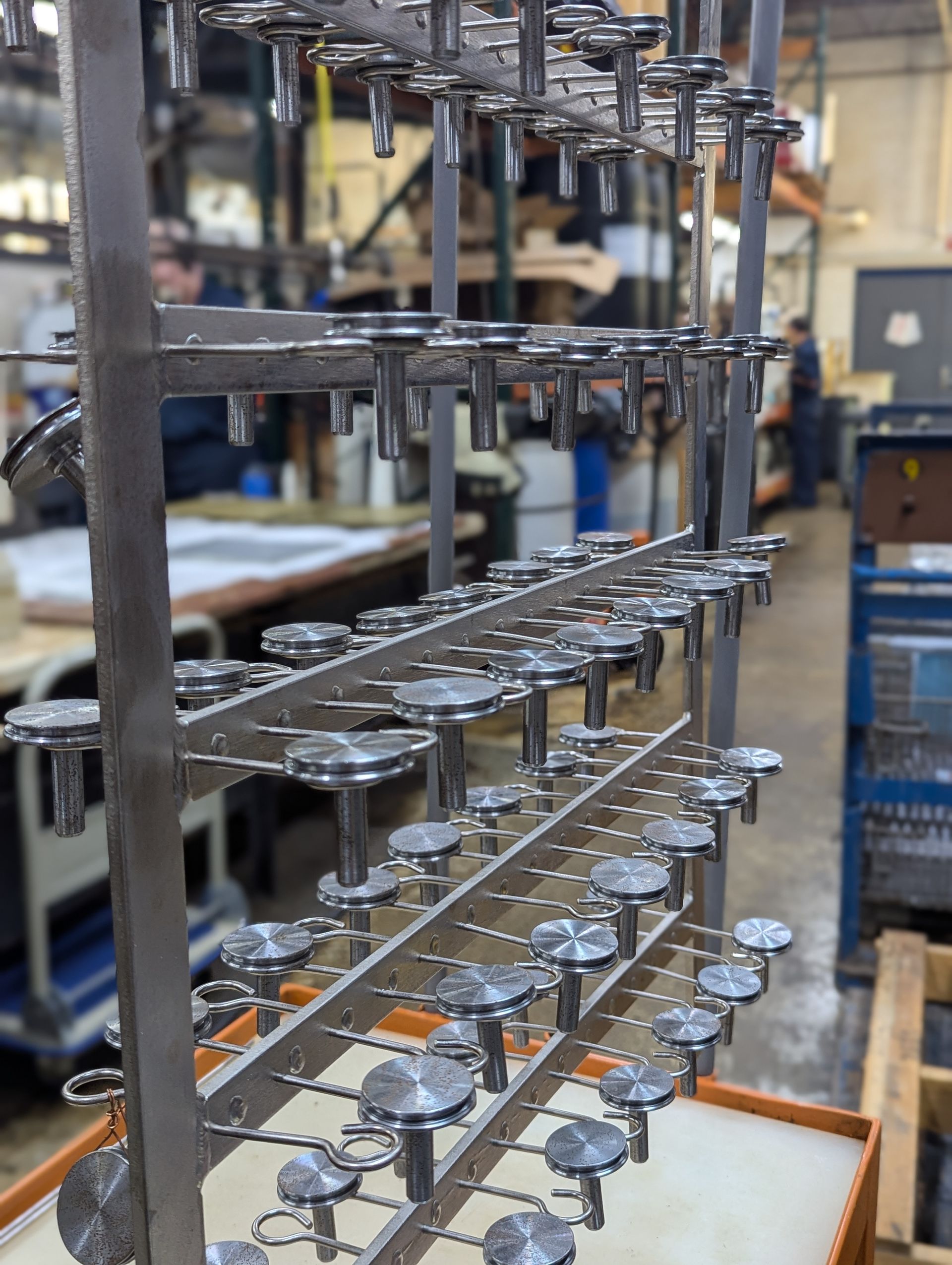

Contracting Micro Plating for RoHS compliant medium phosphorus electroless nickel plating means avoiding potential regulatory fines and issues for your customers. If you supply electronics parts to consumers or an OEM that violate RoHS regulations, you can face steep fines and risk the stability of your business. That makes it especially important to work with an experienced coating company like Micro Plating. For over 25 years we have continually plated molding equipment with complex geometries with medium phosphorus electroless nickel. Our platings comply with not just RoHS laws but can also be applied in adherence to various industry and military standards too. If you want to work with a team that will plate your electronics manufacturing equipment successfully and do so in a way that keeps you in regulatory compliance, contact Micro Plating today.

Medium Phosphorus Can Be Alloyed to Meet Your Needs for Hardness and Industry Specs

Medium phosphorus electroless nickel is an alloy that contains between 6-9% of phosphorus in its chemical makeup. The degree of phosphorus it includes is going to help dictate the alloy’s hardness as plated. This hardness will have a Rockwell score between 54-65 without requiring heat treatment. In addition to their flexibility of as-plated hardness, medium phosphorus electroless nickel can also be alloyed to meet various ASTM specs, Mil-specs, and more, all while remaining within RoHS compliance.

Micro Plating Is Ready to Plate Your Electronics Parts Within RoHS Compliance

Our facility in Erie, PA provides us with plenty of space to take on new RoHS compliant medium phosphorus electroless nickel plating projects and we are ready to complete yours. Our team is experienced, highly skilled, and J.I.T. trained. This combination of skill and practicing successful processes guarantees that each plating job we accept will be handled promptly and correctly. You can work with us to determine the right hardness for your coating as-plated and let us know if your plating needs to meet any industry specs in addition to adhering to RoHS requirements. We want to provide you with the exact plating you need and the more information you can share with us will help us accomplish this.

When it comes to RoHS compliance, you cannot risk prohibited metals being included in the plating equipment you use to produce for your part(s). Contracting the expert team at Micro Plating will ensure your electronics molding equipment is protected from corrosion, wear and tear, and causing RoHS violations.

Request Medium Phosphorus Platings