Phosphorus Level Options from Electroless Nickel Suppliers

Phosphorus Level Options from Electroless Nickel Suppliers

Electroless nickel plating is commonly used throughout various industries including aerospace, defense, automotive, and more. This service is further tailored to specialty applications by changing the phosphorus concentration in the plating solution to provide enhanced durability, aesthetic appearances, and levels of corrosion resistance. Depending on the phosphorus content, electroless nickel plating can be considered low phosphorus, medium phosphorus, or high phosphorus. By partnering with an electroless nickel supplier that offers several different phosphorus options, you will have a wider range of solutions to implement into your projects.

Phosphorus Level Concentrations

The amount of phosphorus content in electroless nickel plating is classified into low, medium, and high categories based on percentage measurements. The following is how plating is classified based on phosphorus makeup.

Low Phosphorus (1-4%) Properties

Electroless nickel plating with low levels of phosphorus tends to provide a high level of hardness alongside quality wear resistance. Compared to other phosphorus content options, low phosphorus typically offers a lower corrosion resistance, so it is not commonly used in applications exposed to harsh environments.

Medium Phosphorus (5-9%) Properties

Medium phosphorus electroless nickel plating is the most commercially used kind of nickel plating, as it offers a premium combination of hardness and wear resistance properties. It is not quite as hard as low phosphorus plating and medium phosphorus plating’s corrosion resistance can be decreased after heat treatment, but it still offers a viable solution for companies that need plating with a good degree of hardness while still offering an aesthetically pleasing finish.

High Phosphorus (>9%) Properties

High phosphorus plating excels at protecting components in acidic and corrosive environments with exceptional corrosion resistance. Even when high phosphorus components undergo additional heat treatment to increase hardness, the amount of corrosion resistance lost still puts it close to what medium phosphorus plating offers standard before heat treatment. In scenarios where you need both hardness and corrosion resistance, high phosphorus plating is likely the solution.

Industries Seeking Electroless Nickel Suppliers

Given the range of beneficial properties electroless nickel plating can have due to the varying phosphorus levels, it applies to numerous industries with different requirements for hardness, corrosion resistance, and plating thickness.

Applications of Low Phosphorus Electroless Nickel Plating

Low phosphorus electroless nickel plating tends to be the option with the greatest hardness, so it is often used in environments that require exceptional wear resistance. Its corrosion resistance can also be good when used in alkaline environments. Plus, the coating can be soldered easily, so it is especially useful in applications that may require those kinds of modifications.

Industries Served

- Automotive - heat sinks, differential pinion ball shafts, disk brake pistons, mufflers, shock absorbers, air conditioning compressor components

- Electronics - Lead wire terminals, interlocks, connectors

- Defense - Radar wave guides, detonators, fuse assemblies

- Oil and gas - Reactors, pressure vessels, pumps and impellers

- Textile - Feeds and guides, loom ratchets, spinnerets, knives

Applications of Medium Phosphorus Electroless Nickel Plating

Medium phosphorus electroless nickel plating offers versatile levels of corrosion resistance and hardness to apply to a wide range of applications, which makes it the most commercially used kind of electroless nickel plating. It is commonly found in electronics with plating across the entire medium phosphorus range. Alternative applications for decorative uses are available with phosphorus levels closer to 4%.

Industries Served

- Electronics - Junction fittings, printed circuit boards, diodes

- Manufacturing - Hydraulic cylinders and shafts, link drive belts, gears

- Aerospace - Servo valves, compressor blades, piston heads, gyro parts, engine mounts

- Medical - Disposable surgical instruments, pill sorters, feed screws

- Defense - Motors, firearms, mirrors

Applications of High Phosphorus Electroless Nickel Plating

Since high phosphorus plating offers such high corrosion resistance, it is frequently used in applications within corrosive environments. This is the kind of plating commonly used in the oil and gas industry alongside any industry that utilizes harsh chemicals. By opting for a high phosphorus solution from an electroless nickel supplier, businesses are able to reduce overall costs for parts and components by helping them last longer with increased thickness and corrosion resistance.

Industries Served

- Chemical - Mixer shafts, heat exchangers, turbine blades, hydraulic system actuators

- Oil and Gas - Filters and components, valves

- Rail - Tank cars, diesel engine shafts, hardware

- Marine - Pumps and marine equipment

- Mining - Mine engine components, piping connections, hydraulic systems

Material Composites

In addition to phosphorus levels, electroless nickel plating can be customized through the use of certain composites. At Micro Plating, we offer a proprietary electroless nickel deposit that includes a homogenous dispersion of Hexagonal Boron Nitride particles called MicroSilk. This composite offers a similar hardness and lubricity to low to medium phosphorus electroless nickel plating, but the coating can be heat treated when used in applications that have high wear conditions. This composite material may be the ideal solution in certain applications in which hardness is a primary concern. When heat treated, MicroSilk can reach a hardness of 62Rc, a level that is inferior only to diamond.

Why Phosphorus Content Matters

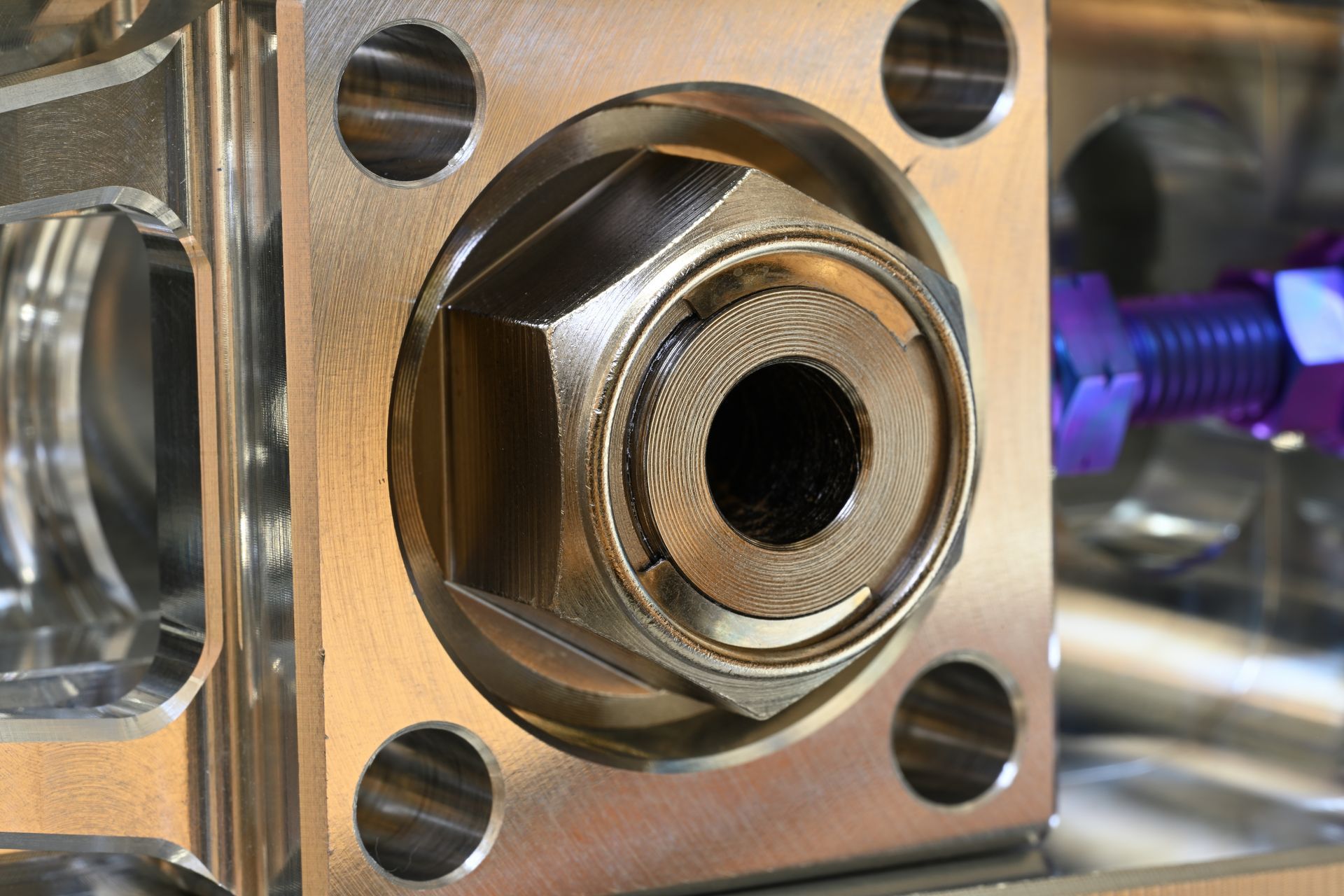

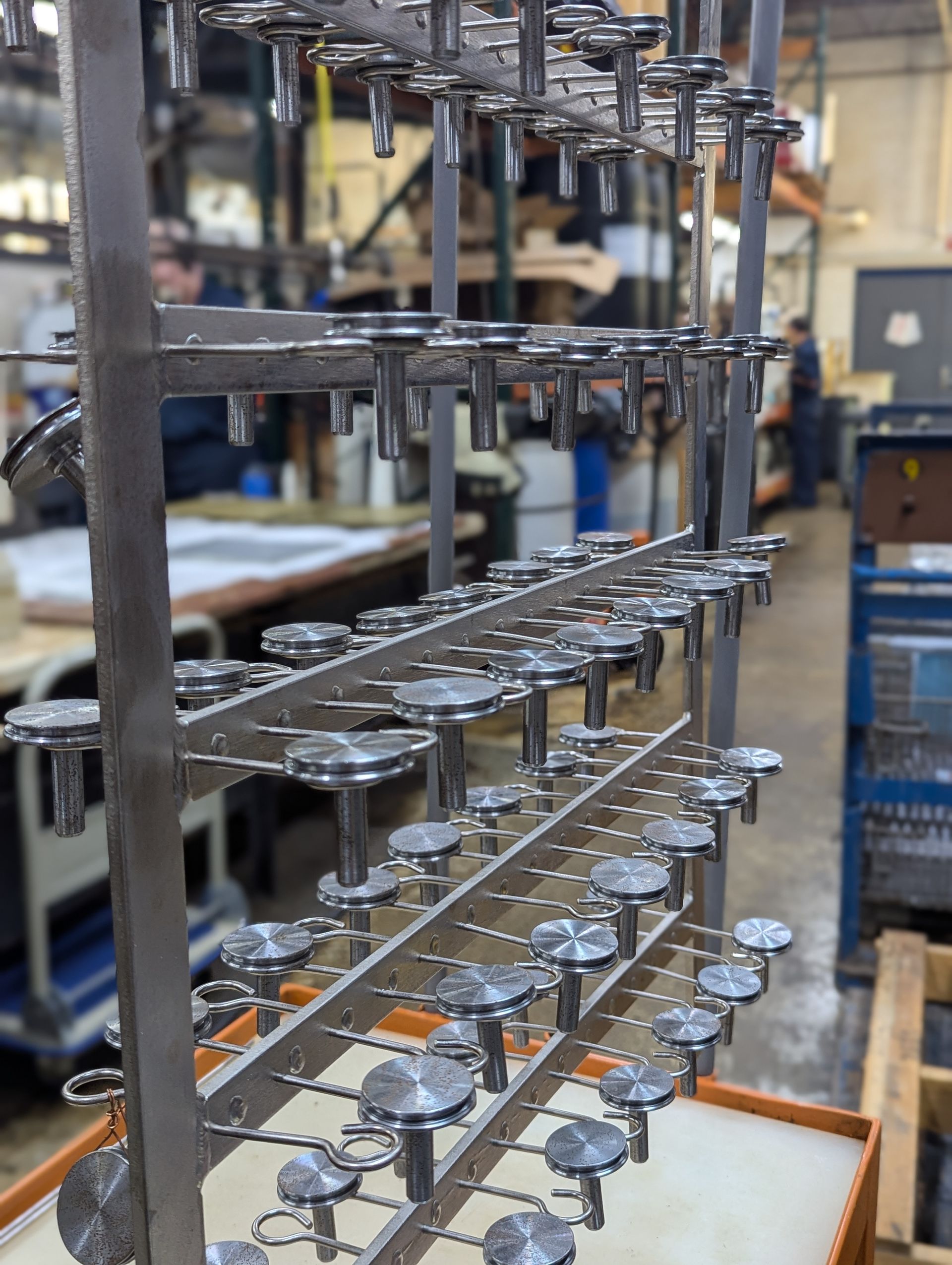

When implementing electroless nickel plating treatments, you can expect several notable benefits that are included regardless of the phosphorus level. For example, electroless nickel plating is applied uniformly across the entire substrate. This includes workpieces with complex shapes, angles, slots, holes, and even internal tubing.

Utilizing electroless nickel plating with the optimal phosphorus content, however, can decrease costs by extending the service life of components significantly. With increased wear and corrosion resistance, parts will take longer to wear down to the point where performance is compromised. Electroless nickel alternatives like carbon steel simply cannot offer that kind of longevity in many applications.

Why Choose Micro Plating

Micro Plating is an experienced electroless nickel plating supplier with options for different phosphorus levels based on your needed application. As a service-oriented business in Erie, we operate with the customer in mind before anything else. Our team will work with you to determine the right solution and phosphorus content for your unique needs. When you reach out to us, you will always be put into contact with a real human person rather than robotic prerecorded messages and extensions. While our Enterprise resource planning software was produced specifically for the plating industry, our team is happy to work with you to fulfill any special requests you may have.

All of our plating services meet or exceed the requirements listed in the

MIL-C-26074,

ASTM B733,

AMS2404, and

AMS2454 specifications. Couple that with our Quality Program’s compliance with

MIL-I-45208 and an average of 25 years’ experience among our staff, and you can expect quality results no matter what your project is. We have an in-house lab and chemist who can process solutions that go beyond altering phosphorus levels to create unique properties that match strict manufacturer specifications.

Contact our team today to request a quote for your next project’s electroless nickel plating requirements.