Nickel Phosphorus Plating Services for High Lubricity

Nickel Phosphorus Plating Services for High Lubricity

Nickel Phosphorus Plating Services for High Lubricity

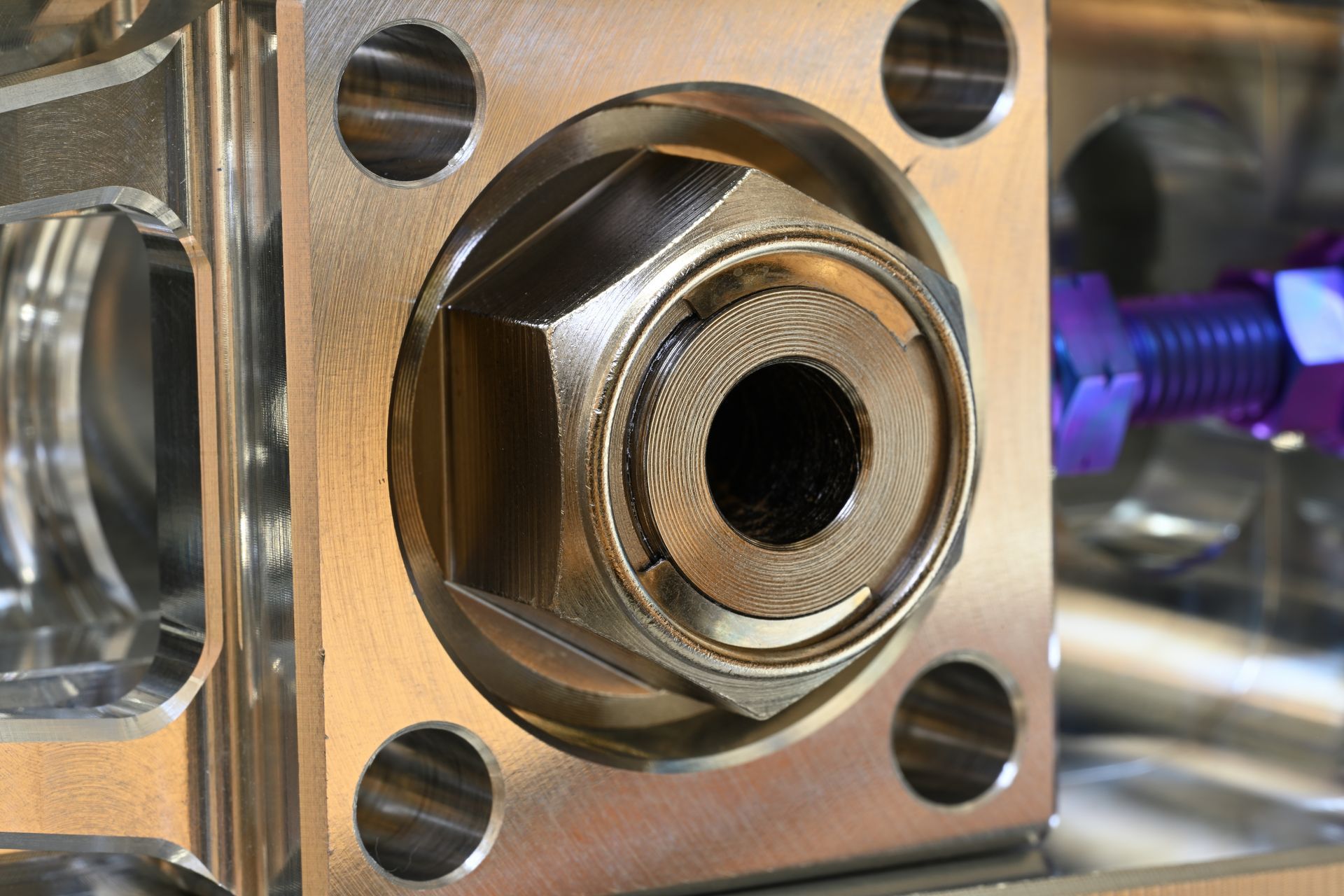

Coating parts with the right blend of nickel and phosphorus can increase hardness, provide corrosion protection, and improve lubricity. When a materials innate lubricity is not well suited to its intended use, we have solutions that can help.

Micro Plating offers multiple types of nickel phosphorus plating services for high lubricity. From traditional options like Medium or High-Phosphorus electroless nickel to proprietary coatings, we are your source for platings that are both protective and friction reducing.

Throughout the remainder of this article, you can learn specifics about our nickel phosphorus platings as well as our proprietary solutions that include these elements along with other compounds that can help you reduce the coefficient of friction of your parts and equipment.

Request Nickel Phosphorus Plating

Phosphorus Adds Lubricity to Nickel’s Hardness and Corrosion Resistance

Nickel is an excellent metal to use for an endless range of plating jobs. While it provides benefits that include natural hardness, wear resistance, and corrosion protection, it can lack the low coefficient of friction needed by some parts. In these cases, including phosphorus in the electroless nickel plating blend can provide the perfect solution.

Choose Between Medium or High Phosphorus Nickel Phosphorus

Our standard electroless nickel coatings are made up of either a medium-phosphorus alloy or high-phosphorus alloy. This percentage of phosphorus in an alloy is what determines whether it qualifies as either a medium or high-phosphorus nickel coating. To help you understand the specifics:

- Medium or mid-phosphorus alloys have 6-9% phosphorus in their makeup

- High phosphorus nickel alloys include between 10-12% phosphorus

Beyond determining how the plating is described, the degree of phosphorus in the alloy you select will also determine the lubricity of your coated part. The need for lubricity varies wildly when coating a part and we can flexibly alloy your plating to include the right amount of phosphorus to match your unique needs.

Hard Data on the Lubricity of Our Nickel Phosphorus Platings

Before contracting our team to perform nickel phosphorus plating services for high lubricity on your behalf, we can quantify the benefits it will provide. If you opt for medium phosphorus plating, it will provide a coefficient of friction of 0.38. With our high phosphorus electroless plating, your parts will have a coefficient of friction of 0.4. If your job demands even greater lubricity, one of our proprietary platings may prove to be a better fit. We will now introduce you to both of these extremely high lubricity coatings.

Micro Plating’s Proprietary Platings Offer Exceptional Lubricity

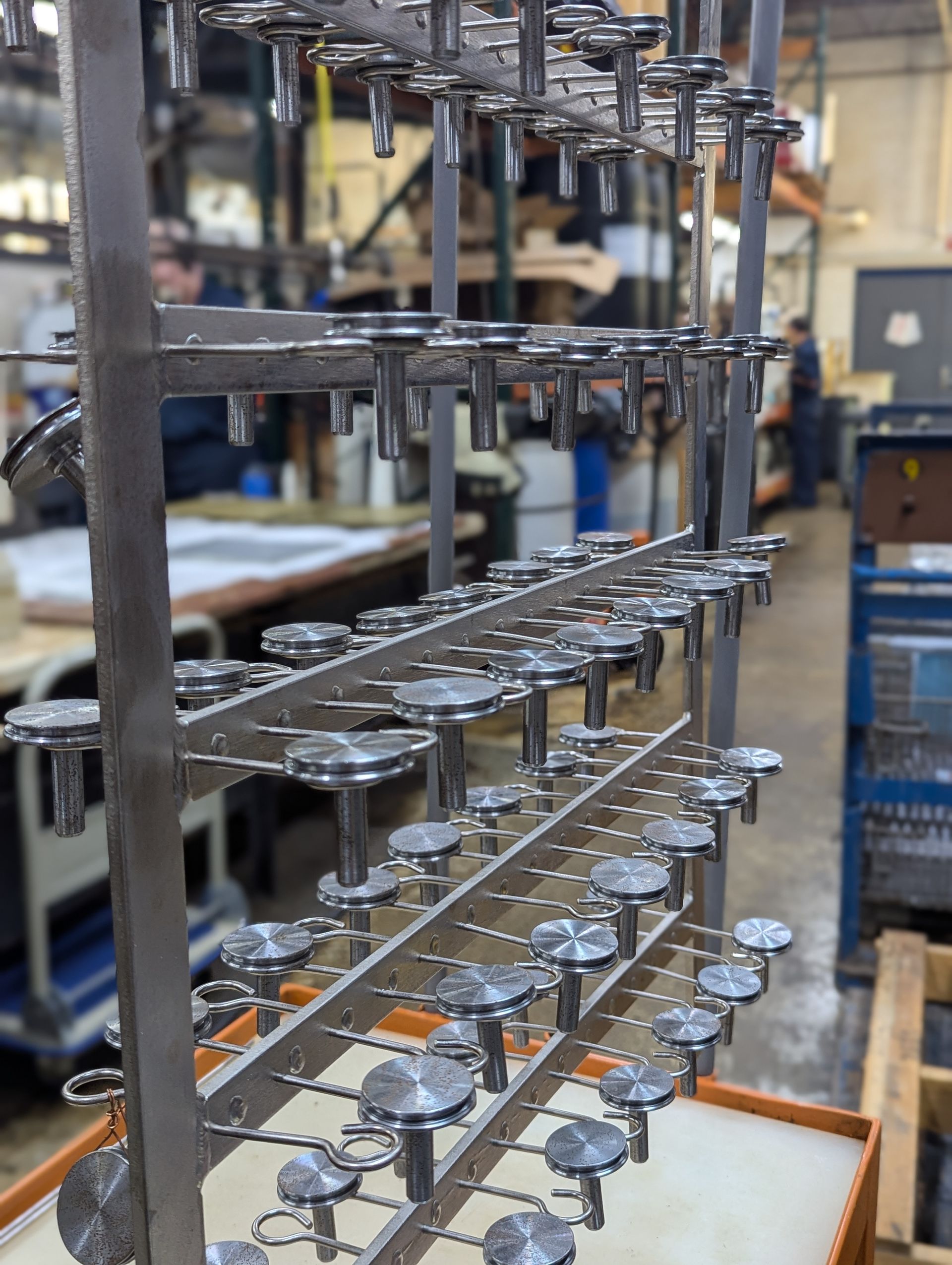

Sometimes a substrate demands a specialized plating solution that will provide even greater lubricity than our standard medium or high phosphorus platings. To handle these challenges, Micro Plating Inc., has developed MicroLube and MicroSlik.

MicroLube includes PTFE in its alloy, which makes it well suited for low load high friction applications. MicroLube is hydrophobic, deposited uniformly, and ideal for a wide range of molding applications.

MicroSlik benefits from a homogenous dispersion of boron nitride. Our customers have found MicroSlik well-suited as a coating for stamping tools, automotive parts, packaging equipment, and friction prone equipment. MicroSlik’s excellent lubricity also makes it great for parts that are exposed to sticky substances, such as adhesive machines and more.

High Lubricity Coatings Will Adhere to ASTM, AMS, and Mil-Specs

Do you need an AMS, Mil-Spec, or ASTM spec coating? We can provide this for you and make sure that it provides the exact amount of lubricity your job demands. When we perform nickel phosphorus plating services for high lubricity, we can do so in adherence with AMS-2404, AMS-C-26074, ASTM B733, and more. We have ample experience providing platings that meet a range of popular specifications and also comply with REACH and RoHS. If you want to confirm whether we can plate your parts with a nickel phosphorus blend that meets a particular spec we have yet to mention, reach out to us to discuss your project and the information on your spec sheet.

Contact Us for High Lubricity Plating